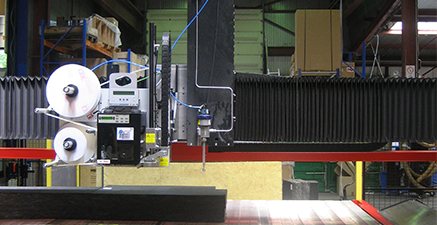

A production line for stone wool panels equipped with a raw material shop, a robot, a conveyor and an automatic labeller: this is the challenge taken up by MÉCANUMÉRIC for its customer specialising in the manufacture of acoustic and air insulation.

At a trade fair, the customer approached us for information on a milling machine.

After several discussions to better understand his needs, we were able to offer him a tailor-made machine including

- a 4-zone magazine for storing raw rock wool sheets by thickness

- a robotic arm to load the raw sheets onto the conveyor

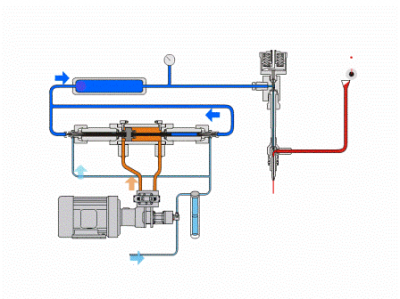

- a water jet cutting head

- an automatic labelling module just after cutting

- the design of software perfectly adapted to their needs.

The customisation even went as far as painting this production line in a different colour than usual so that it would fit in perfectly with the customer's premises.