Plastics

Highly versatile and covering a wide range of applications, the MÉCANUMÉRIC CNC milling machine ranges have long since won over plastics processing operators and their subcontractors. New industrial waterjet cutting equipment completes this offer dedicated to precision and productivity.

In the plastics industry, 3-, 4- or 5-axis CNC milling and 3D machining play an essential role in the transformation of technical plastics due to the diversity of applications they cover. They can be found in fields of activity as varied as the automotive industry, aeronautics, POS advertising and signage.

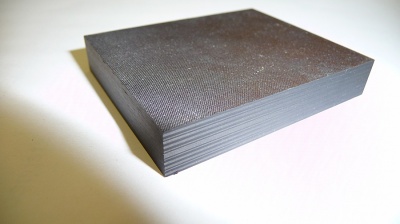

Waterjet cutting completes the multi-technology offer of MÉCANUMÉRIC applied to the plastics industry and its subcontractors to meet all needs, from 3D machining of small technical parts to the processing of large models, including waterjet cutting of foams and seals.

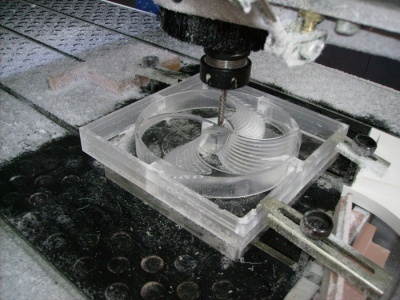

Industrial tools for CNC machining of 3D parts

As a manufacturer of industrial equipment, MECANUMERIC offers CNC machines for the milling of 3D plastic parts such as orthoses for orthopaedics or axes for the manufacture of parts for household appliances for example.

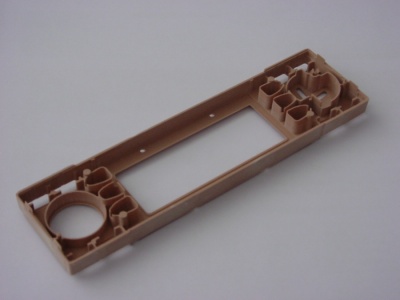

CNC milling machines for the manufacture of technical PVC parts

Technical parts made of PVC are used in many applications. Indeed, CNC machining allows for the customised manufacture of this type of part, which can therefore be integrated into the manufacturing process of various industrial equipment or machine tools. Technical parts in PVC can be produced in small and large series. Prototypes or mouldings can also be made. A 3- or 4-axis digital milling machine allows, for example, the cutting of signage covers for signage and POS.

Industrial equipment for 3D machining of resins

Specialised in the design and manufacture of industrial equipment, MECANUMERIC offers a range of technologies for the 3D machining of resin parts. Indeed, thanks to the use of software that is as efficient as it is easy to use, you can produce resin parts such as housings in the automotive industry, mouldings for the production of models and prototypes.

The digital milling process for the manufacture of technical plastic parts

Many industries, including the pharmaceutical and chemical industries, require the manufacture of technical plastic parts. The production of these parts goes through several stages in order to obtain different types of cuttings by CNC milling and engraving. A single machine, a 3-axis numerical milling machine, for example, allows all these steps to be carried out using numerical control.

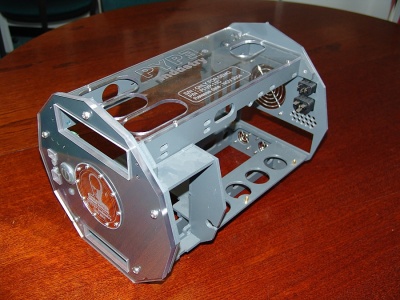

Manufacturing plastic sheet metal parts with CNC milling

Based on its long experience as a supplier of industrial equipment, MECANUERIC offers 3-axis CNC milling machines for the manufacture of plastic boiler parts. Plastic materials are increasingly being used in the manufacture of many items of equipment. For example, digital milling is used for the manufacture of signage panels, tanks for the food industry or ventilation pipes for the aerospace industry.

CNC milling machines for the manufacture of plastic moulds and models

CNC control allows for the simple and rapid manufacture of plastic moulds and models. 3D CNC machining can meet the most diverse needs in applications as varied as the manufacture of rapid prototypes, moulds for the production of series parts for the dental or automotive industries.

MÉCANUMÉRIC multi-technologies and plastics processing: when quality goes hand in hand with productivity

Plastics processing, a relatively recent industry compared to other industrial sectors, is a very buoyant field that benefits from constant innovation, often driven by the very material it uses.

This sector often requires high yields, without sacrificing the quality and precision of finishes, whatever the application for which the production is intended.

MÉCANUMÉRIC's agile and versatile range of multi-technology equipment enables productivity to be increased with high precision and offers quality finishes as well as great flexibility in the generation of the different shapes that the vast field of plastics processing offers, for a wide variety of applications.

A MÉCANUMÉRIC technological solution for every application

With 3-axis milling, the MECAPRO, MECAPLUS and MECAEASY ranges cover a wide range of applications in the processing of technical plastic parts and for the production of plastic boiler making elements. Equipment that perfectly matches the needs of vat makers, moulders and all thermoformers and subcontractors of the plastic industry in general.

The range of mini-milling machines and mini-machining centres (4U, 2U, DMC) completes this technology by allowing 3D machining with the high precision required by the plastics industry in the machining of technical parts in different materials (resin, PVC, etc.), or for the production of moulds and models.

MECANUMERIC's waterjet cutting equipment (MECAJET and QUICKJET II) are ideal for cutting foam or gaskets, combining precision and speed of execution to increase productivity.