MECAPLUS HP

MECAPLUS-HP “AGILE” MACHINING High precision and performance solution

- Description

- Technical datas

- Fields of activity

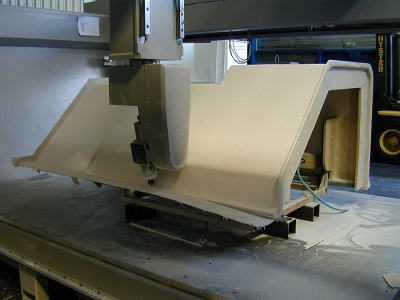

HIGH PRODUCTIVITY 3 axes milling equipment : “AGILE” MACHINING

STRENGTHS

- Designed and realized for an intensive use.

- Heavy, fast, powerful, precise and efficient equipment, easy to operate for the machining of rigid sheetmaterials of strong thickness, in the fields of plastic processing, modelling, aeronautics, aluminium processing… or for the machining of molds and 3D models.

- Particularly adapted for the machining of aluminium, plastic materials of strong thickness and composite materials with high mechanical properties.

- Many customization possibilities.

- Innovative and efficient vacuum tables with turbine technology or vacuum pumps.

- Numerical controls SIEMENS or HEIDENHAIN type.

- Quality kinematics integrating industrial components supplied by the world leaders in their field, mounted on welded stabilized steel frames.

OPTIONS

- Vacuum table technology with two-stage side channel turbine 7.5 kW, 520 m³/h

- Vacuum table technology with four-stage turbine 15 kW, 1500 m³/h

- Vacuum table with vacuum pump 250 m³/h, 4.5 kW

- Tool cooling systems (frozen air, lubrication…)

- Chip and dust suction systems

- On-gantry rotating tool shop, capacity 24 tools (option 40 tools)

- Rigid tapping

- Heidenhain pressurized measurement rules on X, Y and Z axes...

TECHNICAL DESCRIPTION

- Structure: high inertia steel welded mobile gantry.

- Table Top: aluminium table with consumable covering or phenolic resin plate.

- Guidance: precision linear rails with preloaded ball slides on 3 axis.

- Transmission: Ballscrews on the 3 axis. Double ballscrew for the X axis.

- Motorisation: Brushless motors.

PERFORMANCE

- Maxi speed in mm/sec on X and Y : 600

- Maxi speed in mm/sec on Z : 400

- Resolution in mm : 0.001

- Repeatability in mm at 20°C +/- 2° ± : 0.015

DIMENSIONS

| MECAPLUS HP 4321 | |

| X stroke | 4350 |

| Y stroke | 2100 |

| Z stroke | 375 |

| Maximum material width | 2150 |

| Passage under gantry | 600 |

| Length | 6900 |

| Width | 3900 |

| Height | 3300 |

| Weight | 9000 |

Satellites

Bathroom elements

Structure parts and tooling

Boat rudder blade machining

Kitchen elements

Formworks

Household appliances

Aeronautic seats

Aircraft interior furnishing

Side windows

Trolleys

Trucks parts

[TESTIMONIAL] PERSONAL LITE (Visual communication made in Italy)

Creation, design, production and installation of customised advertising signs for the Italian market.

[TESTIMONIAL] Christophe CAUSSE - Director of USITECH (precision mechanics)

USITECH manufactures simple and complex metal parts and accessories for a wide range of sectors.

Machining new materials in the aerospace industry: MÉCANUMÉRIC, expertise at the service of innovation

Advantages, issues and machining problems: composites offer significant advantages in the aeronautical sector, but what are the challenges to be met in order to benefit from them?

![[TESTIMONIAL] PERSONAL LITE (Visual communication made in Italy)](/medias/articles/vignettes/logo-pl_1_1.jpg)

![[TESTIMONIAL] Christophe CAUSSE - Director of USITECH (precision mechanics)](/medias/articles/vignettes/usitech-brens_1.jpg)