CHARLYDENTAL CD05-S/CD05-HP

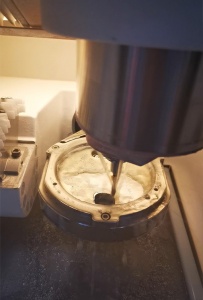

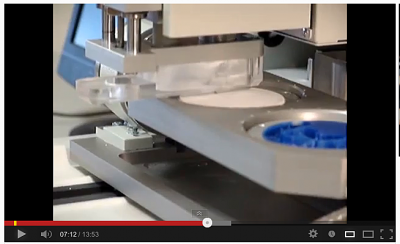

Machining machines for dental prostheses in 5 positioned axes, ideal for a simple and fast daily production of prostheses in soft and ceramic materials, dry or with lubricated tool.

- Description

- Technical datas

- Fields of activity

Very compact in size thanks to the original choice of kinematics, they offer maximum versatility in a minimum of space.

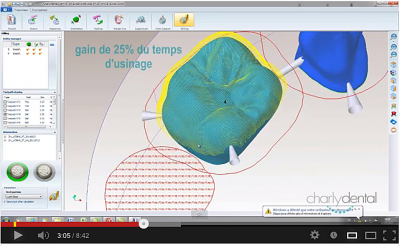

They are equipped with an open CAD / CAM system capable of being used with the main scanners, CAD / CAM software and consumables in the dental sector.

Other strong points of this concentrate of design and manufacturing innovation "100% French":

- Power reserve by 500 or 980 W spindle - 60,000 rpm and brushless servomotors.

- Flexibility and precision of machining with angulation of the rotary axes.

- 5th axis: 0 to 180 °.

- Precision by quality kinematics, ball screws and rectified rails.

- Easy to use thanks to its color touch screen and user-friendly machine control software.

- Efficient automatic management of tool changes and sister tools, detection of tool wear and breakage.

TECHNICAL CHARACTERISTICS

- Brushless servo motors

- Spindle 500 or 980 W / 60,000 rpm

- Automatic tool change (with 12 tools in the changer)

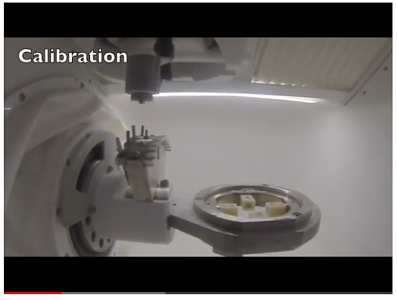

- Precision measurement of tool length

- Tool breakage detection

- Tool wear detection

- Integrated suction sensor

- Communication port: 1 USB and 1 ETHERNET

- Power supply: 230 VAC 50/60 Hz

DIMENSIONS

| CD05-S | CD05-HP | |

| Lenght | 542 | 542 |

| Width | 600 | 600 |

| Height | 737 | 737 |

| Weight | 100 | 100 |

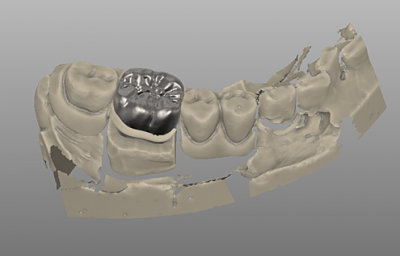

Realising single cap and bridgeworks

Automatic undercut milling on charlydental 4 axes (video)

Charlydental 4X (video)

4 or 5-axis machines CD04-S, CD-05-S (video)

Crown in Lithium Disilicate block

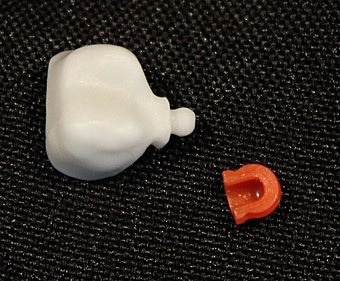

Execution of orthondic trays

Execution of rest trays

Execution of orthodontic study models

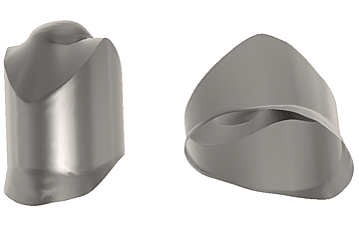

Execution of implant abutment with pre-milled technology

Execution of single crown

Execution of telescope crown

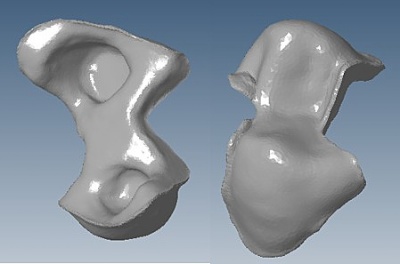

Execution of bridge

Execution of single framework (cap) and bridge

Execution of temporary crown and bridge

Execution of customised implant

Execution of screwed-in bar

Execution of implant guide

Execution of framework (Stelitte, Squelette…)

Execution of dental model

Execution of Inlay-core

Execution of inlay onlay

Execution of denture

Special execution

[TESTIMONIAL] POLIMATRIX - Creations in polystyrene and other materials

Solutions for construction, prototyping and scenographic installations.

[TESTIMONIAL] Christophe CAUSSE - Director of USITECH (precision mechanics)

USITECH manufactures simple and complex metal parts and accessories for a wide range of sectors.

[TESTIMONIAL] Audrius BUTKEVICIUS - RD SIGNS (Signage)

RD SIGNS produces outdoor advertising media for a large number of customers in Europe.

![[TESTIMONIAL] POLIMATRIX - Creations in polystyrene and other materials](/medias/articles/vignettes/logo-polimatrix-img_1_1.jpg)

![[TESTIMONIAL] Christophe CAUSSE - Director of USITECH (precision mechanics)](/medias/articles/vignettes/usitech-brens_1.jpg)

![[TESTIMONIAL] Audrius BUTKEVICIUS - RD SIGNS (Signage)](/medias/articles/vignettes/logo-rd-signs_7.jpg)