QUICKJET II

Compactness and precision for all materials

- Description

- Technical datas

- Fields of activity

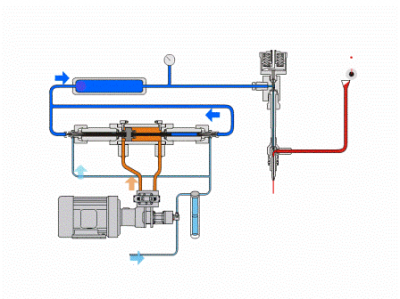

MECANUMERIC's new QUICKJET II waterjet cutting machine is unique on the market, combining safety, compactness, high productivity and ultra-precision.

Its kinematics, inspired by mechanical machining centre solutions (use of ball screws on all axes and high-performance AC brushless servomotors controlled by a user-friendly numerical control), means it can be used to produce high-precision parts.

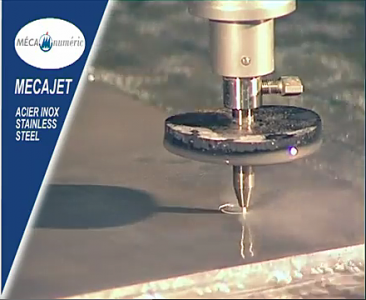

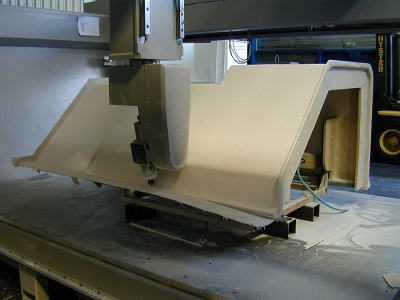

Equipped with high-pressure pumps and THP components from world leader KMT Waterjet, the QUICKJET II waterjet cutting machine is optimised for all precision industrial cutting applications, using a pure waterjet for soft materials (rubber, plastic, cardboard, textiles, leather, paper, foam, etc.) or with the addition of abrasive for all hard materials (steel, aluminium, stainless steel, titanium, minerals, glass, ceramics, composites, etc.).

The possibility of operating in immersion (automatically variable water level) offers great ease of use and a significant reduction in noise and splashing. The optional sludge treatment system and five-axis head further enhance productivity.

This fully enclosed equipment is particularly well-suited to safe use in schools and universities.

STRUCTURE

- High inertia steel welded structure cast in one piece

- Welded aluminium mobile gantry

- Stainless steel tank

- Table with coating adaptable to different materials : zinc coated gratings , S bars or plastic honeycomb coating

KINEMATICS

- Guidance by grinded steel rails and preloaded ball bearings

- Transmission by preloaded ball screws on XYZ axes (double motorisation on X axis)

- Motorisation by servomotors « AC Brushless »

PERFORMANCE

- Maximum speed in m / min: 30

- Acceleration in m / s²: 2

- Accuracy in mm: 0.08

- Repeatability in mm at 20 ° C +/- 2 °: 0.05

DIMENSIONS

| QUICKJET II | |

| X stroke | 1020 |

| Y stroke | 1260 |

| Z stroke | 205 |

| Maximum material width in mm | 200 |

| Maximum load on table in kg/m2 | 400 |

![[TESTIMONIAL] SIAN S.N.C. - Engraving and visual communication](/medias/articles/vignettes/logo-sian-snc_1_1.jpg)

![[TESTIMONIAL] Franck RENDA - President EUROTECH-RENDA EUROTECH RENDA (Refractory Materials)](/medias/articles/vignettes/eurotech-renda_1.jpg)