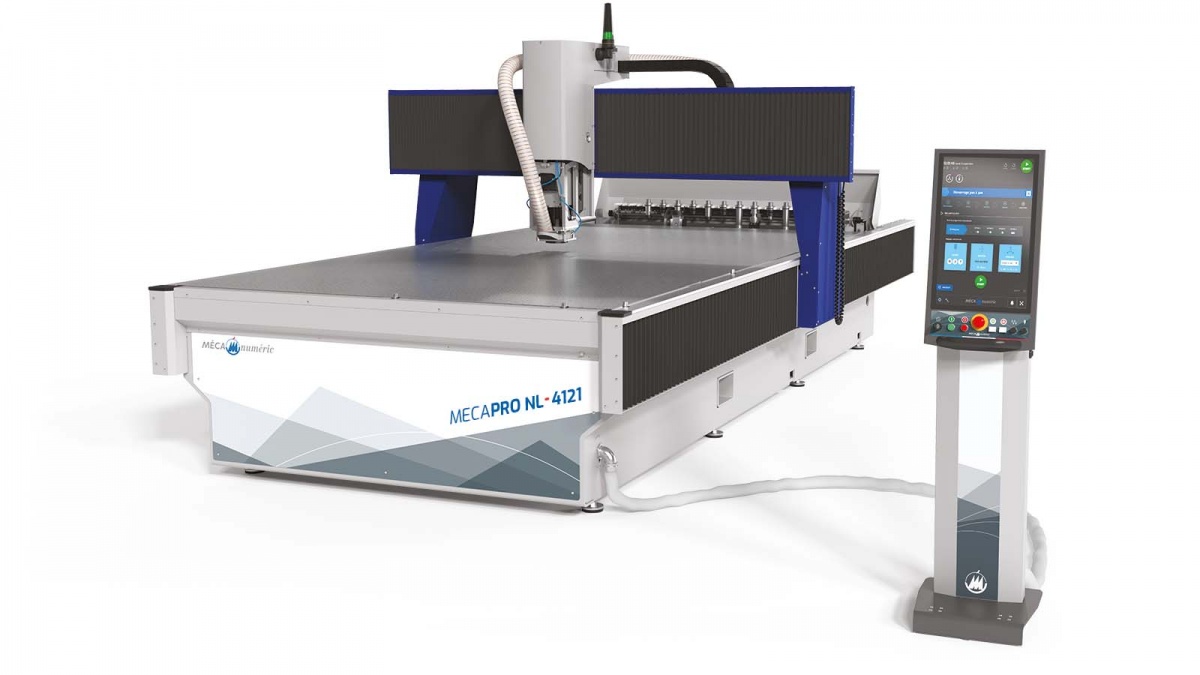

MECAPRO NL

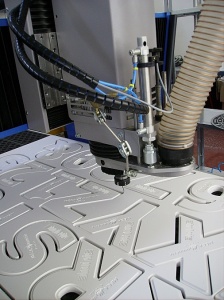

Efficient, versatile & adaptable cutting equipment for many fields

- Description

- Technical datas

- Fields of activity

Designed for intensive industrial use

Working area adapted to new plate dimensions (working width 1600 or 2100 mm) for a wide range of plate and unrolled materials :

- Polymers : PMMA, PEHD, PS, PET, PETG, PU, PC, ABS, PVC…in solid or honeycomb panels

- Wood and its by-products: MDF, TRESPA and others phenolic derivatives, natural wood…

- Lights alloys : Aluminium, Brass, Copper, Zinc…

- Composites : Alucobond®, Dibond® and similar, Glass/Epoxy, Carbon/Epoxy…

- Honeycomb panels: Nida®, Nomex®…

- Machinable plates for molds and models

- Hard materials only under conditions: Steel, Stainless Steel, Titanium

- Mineral base panels for ITE

- Rubber and derivatives

- Foams with all densities

- Paper, cardboard and derivatives

- Plastics with small thickness (PVC, PS, PET, PETG, ABS, PC…)

STRENGHTS :

VERSATILE AND CUSTOMIZABLE EQUIPMENT :

- High-speed machining (HSM)

- Secondary pre-installed functions (heads non included): knife-cutting with tangential control, creasing by shaped wheels, cutting by disc blade, rigid tapping...

- Secondary optional functions: angle sawing, angle head, camera registration, tool cooling...

POWERFUL ELECTROSPINDLE WITH HIGH ROTATIVE SPEED

- 2 models available

- 4 ceramic bearings

- Shock, vibration and temperature sensors with digital control alerts

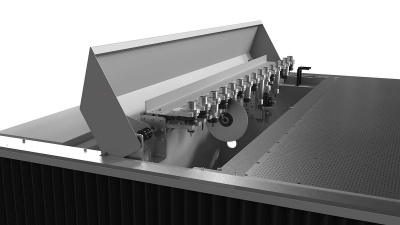

PRE-SET TOOL SHOP FOR ALL TYPES OF TOOLS AND HEADS

- 8 to 15 locations

- Including 4 to 6 combined locations for: cones for vertical tools, cones for tangential control heads, cones for angle heads

- Laser sensor for contactless measurement of tool length and diameter or the geometry and location of blades

DESIGNED TO LIMIT THE IMPACT ON THE ENVIRONMENT

- Position-controlled chip suction nose

- Vacuum table with variable power from 40 to 100% to always have the correct plate holding level with no electrical overconsumption

NUMERICAL CONTROL LATEST GENERATION

- 21 inches vertical touch screen on mobile control panel

- Modern, simple and user-friendly HMI with online operator guidance (to avoid oversights and errors)

TECHNICAL DATA

- Structure : Monobloc chassis and mobile gantry in mechanical welded high inertia steel

- Table : Aluminium fixed table with consumable top cover in option

- Guidance : Grinded prismatic rails and preloaded ball bearings.

- Transmission : Ball screw with preloaded nuts on all axes (two ball screws on X axis)

- Motorisation : Brushless motors with absolute encoders on all axes (two motors on X axis)

DIMENSIONS

| MECAPRO NL 1621 | MECAPRO NL 3116 | MECAPRO NL 3121 | MECAPRO NL 4121 | |

| X axis travel in mm | 1600 | 3100 | 3100 | 4100 |

| Y axis travel in mm | 2100 | 1600 | 2100 | 2100 |

| Z axis travel in mm | 325 | 325 | 325 | 325 |

| Passage between uprights (reference points not used): over the first 100 mm / the entire height above the table |

2200 / 2100 | 1700 / 1600 | 2200 / 2100 | 2200 / 2100 |

| Passage under gantry or under spindle nose in mm | 380 | 380 | 380 | 380 |

| Length in mm (pumps not included) | 3020 | 4600 | 4600 | 5600 |

| Width in mm | 3100 | 2600 | 3100 | 3100 |

| Height in mm | 2700 | 2700 | 2700 | 2700 |

| Average weight in kg | 3800 | 4000 | 4500 | 5000 |

POWERFUL ELECTROSPINDLE WITH HIGH ROTATIVE SPEED

| HSD951-SM-A8 | HSD951-SM-W12 | |

| Maximum power S1 - S6 in kW |

8 - 9,6 | 12 - 14,4 |

| Max torque S1/S6 | 6,4 / 7,7 Nm to 12 000 rpm |

9,5 / 11,4 Nm to 12 000 rpm |

| Rotation speed rpm | 0 to 28 000 rpm | 0 to 28 000 rpm |

| Coolant | AIR | WATER |

| Cooling | Fan | Regulated cooling unit |

| Tool changing | Automatic, HSK-F63 | Automatic, HSK-F63 |

Building façades

Milling of foam

Furniture

Satellites

Decorative friezes

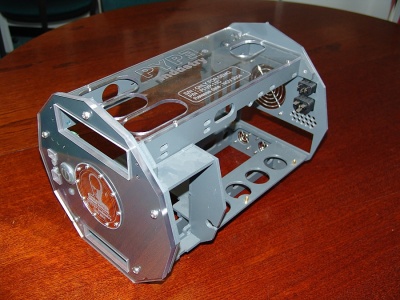

Cases and boxes

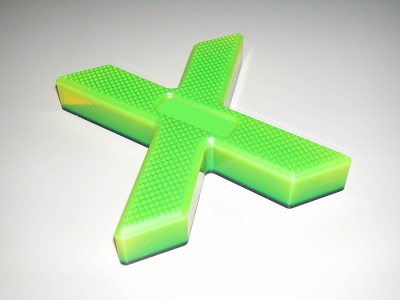

Rapid prototyping

Part for POS application

Relief sign in wood by product (MDF)

Marking

Structure parts and tooling

Technical plastic parts

Parts for racing motorcycles

Parts for the train industry

Formworks

Plastics and PVC frames

Aluminium frames

Household appliances

Aeronautic seats

Aircraft interior furnishing

Side windows

Trolleys

Bus parts

Parts for trams

Parts for subways

Trucks parts

Electric vehicles parts

Moulds and models

PVC signboard

[TESTIMONIAL] Trasparente (graphic arts and visual communications)

Trasparente manufactures all types of signs for the Italian market: raised, illuminated, two-sided, cut-out or complete with LED lighting, advertising panels and signage panels.

[TESTIMONIAL] Elora GOURAUD - MOCN Technician Manager - ADP ENSEIGNES (Signage)

ADP Enseignes has specialised in the manufacture of signs, signage equipment and fittings since 1984.

[TESTIMONIAL] POLIMATRIX - Creations in polystyrene and other materials

Solutions for construction, prototyping and scenographic installations.

![[TESTIMONIAL] Trasparente (graphic arts and visual communications)](/medias/articles/vignettes/logo-trasparente-black_1_1.jpg)

![[TESTIMONIAL] Elora GOURAUD - MOCN Technician Manager - ADP ENSEIGNES (Signage)](/medias/articles/vignettes/temoignage-adp-enseignes_2.jpg)

![[TESTIMONIAL] POLIMATRIX - Creations in polystyrene and other materials](/medias/articles/vignettes/logo-polimatrix-img_1_1.jpg)