MECANUMERIC : Manufacturer of CNC machines

CNC machines designed and manufactured in France

Our CNC machining centres are unique thanks to our 100% integrated production in our factory in south-west France. We take care of all our machines, from research and development to design and manufacture, right through to final testing. The constant evolution of cutting and machining technologies offers the various players in the industry numerous advantages for improving industrial performance.

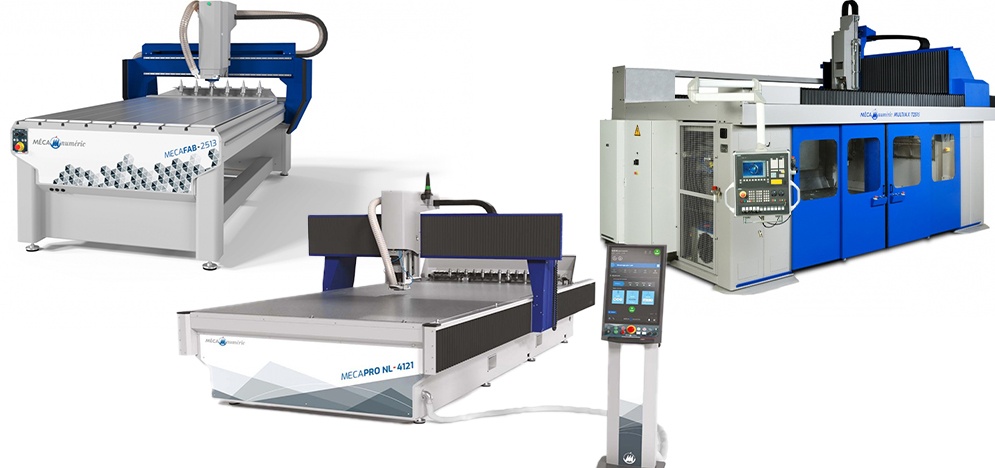

Standard CNC machine tools

MECANUMERIC, a French manufacturer of machine tools, is committed to providing a CNC solution to every industrial problem, thanks to its areas of expertise in milling, water jet cutting, knife cutting, turning, laser cutting and thermoforming.

A wide range of 3-axis CNC milling machines

3-axis CNC milling meets a wide range of industrial needs. Discover all our 3-axis milling solutions, from high-precision mini machining centres, compact milling machines and milling machines offering excellent value for money, to high-performance cutting and milling solutions for small and large parts.

3-axis milling machines are the most widely used in industry, as they are highly versatile for cutting and machining a wide range of materials in a multitude of sectors: sign production, technical mechanical parts, electronics, luxury goods and crafts...

This wide range of applications also means they can be used successfully in the construction and model-making sectors, where 3-axis milling is ideal for cutting plastic joinery, decorative friezes and 3D wooden bas-reliefs.

4-axis milling machines for industry and dentistry

4-axis CNC milling machines offer high productivity. This milling system allows work to be carried out on the sides and surface of the part. This means that the operator does not need to turn the material during the process.

Our MECABOND model is suited to industrial sectors requiring rapid cutting of sheet materials such as alucobond. A saw on the 4th axis enables rapid cutting of panels for decoration or facades.

The CHARLYDENTAL range of milling machines is designed for the dental sector (laboratories, prosthetists, dentists) for the production of dental prostheses in soft materials (disilicate, wax, resin, etc.) or ceramic.

High-performance, versatile 5-axis milling machines

Two ranges of 5-axis milling machines are available from MÉCANUMÉRIC. The first is designed for the dental sector, with CHARLYDENTAL milling machines featuring 5-axis CNC technology for the production of technical prostheses.

The second is designed for industry, and more specifically for machining large parts in the plastics, aerospace and ground transport sectors. This range of CNC milling machines is versatile, and also meets the needs of modellers and thermoformers, providing perfect deburring and finishing of large plastic parts.

Compact CNC turning machines

Our Charly4T turning machine is particularly compact. The main turning operations, such as facing, turning, grooving, reaming, drilling, threading and following complex profiles, are all possible with this training lathe. What's more, its ease of use makes it particularly well-suited to training in secondary schools and apprenticeships. This process is widely used for turning prototypes and small production runs in Fablabs and local factories.

CNC laser cutting machines

Laser cutting is as precise as water jet or knife cutting. It is particularly suitable for mass production. Many materials can be machined using this process (wood, metal, acrylic, plastic, leather, etc.).

CNC water jet cutting machines

The range of water jet cutting machines has been designed to cut all types of material, whether soft, flexible or hard. Depending on the material to be cut, cutting can be carried out using pure water or with the addition of an abrasive (sand). Cutting is carried out using cold water. No deformation is produced by the heat.

This technique is particularly well-suited to industrial applications with stringent hygiene requirements, such as in the food processing or medical sectors. In the mechanical engineering sector, waterjet cutting can be used to cut precision technical mechanical parts in stainless steel, for example. Water jet cutters can also be used to cut very hard natural materials such as marble, granite, stone, etc.

Knife-cutting machines

The knife cutting system has been modernised with the arrival of numerical control. However, this technique is still easy to use and inexpensive to run. Different types of knife can be adapted to this type of machine. They can cut light, flexible materials with great precision and speed.

This technology is particularly well suited to the packaging, adhesive and textile industries.

Industrial thermoforming machines

Thermoforming is carried out by a semi-automatic vacuum press. Complex parts with high forming depths can be moulded with high repeatability. This type of process allows high speeds, so productivity is excellent.

Thermoforming is therefore ideally suited to the production of seat components in the ground transport and aeronautics sectors.

Customised CNC machines

MÉCANUMÉRIC, a manufacturer of standard machines, also offers customised solutions. We offer our customers custom-built machines as well as refurbished machines.

Customised machines

The diversity of cutting and machining jobs carried out by our customers in industry is particularly wide-ranging. Their manufacture sometimes requires the implementation of customised solutions through machines developed from standard machines.

These special designs enable us to add functions to our machines that offer greater production versatility, for a lower budget than that required to build a made-to-measure machine.

Reconditioned machines

The purchase of new equipment by our customers can be an opportunity for them to sell us their old equipment, on the same principle as in car dealerships. Our in-house technicians overhaul, check, improve and recondition this equipment so that it can be offered for sale again at a lower price than that of a new machine. We ensure full reliability and offer a warranty on each piece of equipment.

Tailor-made machines

For more specific requirements, and thanks to our expertise, our in-house engineering department and our many years of experience, we can respond to your special requests by producing a completely customised machine to your specifications.

Customized Equipement

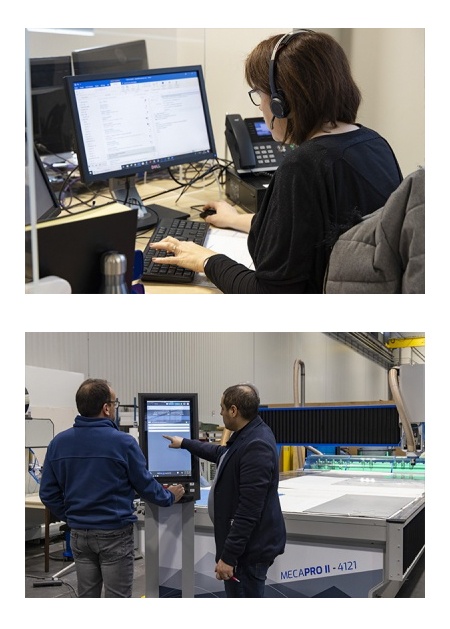

Our services

At MÉCANUMÉRIC, we listen to our customers. Because our machines have a long service life, we offer you long-term support to improve the performance of your machines and provide maintenance services.

Our hotline is at your disposal and does everything possible to limit interruptions to your production. Our itinerant expert technicians and our remote maintenance service are on hand at short notice to provide you with the right solution to your problem.

Mécanuméric: people, technology and solutions

MÉCANUMÉRIC designs, manufactures and markets a wide range of numerically controlled machines in France. Our 3-axis, 4-axis and 5-axis milling machines, our water-jet and laser cutting machines, our turning machines and our thermoforming machines meet your needs whatever your sector of activity.

Many types of material can be machined with a CNC machine: aluminium, wood, steel, plastics, leather, textiles, stone, cardboard, etc. Quality, precision, speed of execution and reduced production costs are just some of the advantages offered by CNC machine tools.

Our software is delivered with your machine. We provide a complete service to our customers upstream of their order. We help them to get to grips with their technological tools. Our technicians are regularly trained to provide the best possible after-sales and maintenance service.

Our expertise, experience and know-how are recognised both in France and internationally.